The Only Way is Up?

Share

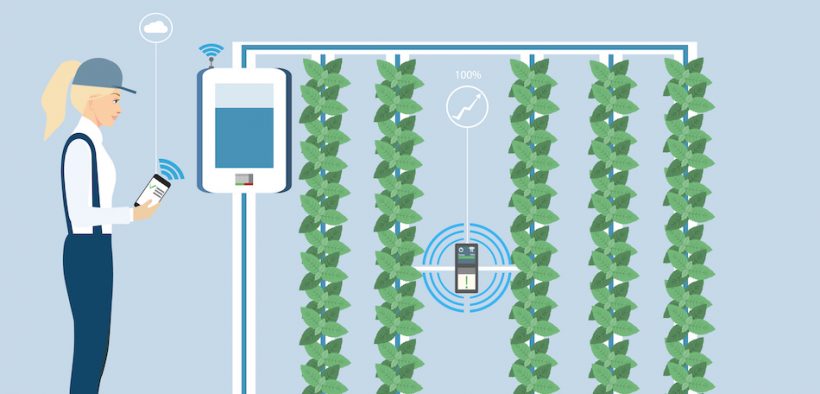

Global food production as we know it is being transformed by a new crop of agriculture technology start-ups that are disrupting the processes of traditional agriculture. Indoor farming, or vertical farming, involves growing produce in large warehouses using artificial light and automated technology. This can reduce water requirements by up to 70% and save greatly on space and soil. Sustainability and eco-friendly methods are key, enabling the possibility of farming in difficult environments.

Vertical farming technologies offer increased crop yield given the lower land requirement, and a larger variety of crops can be cultivated because the crops don’t share the same land while growing. Crops are resistant to weather disruptions, meaning less is lost to extreme or unexpected weather occurrences. Due to the limited land usage, vertical farming is also less disruptive to native plants and animals.

“Bowery Farming raised $95m in a 2018 funding round backed by Google Ventures and Uber boss Dara Khosrowshahi, bringing its total funding to $122.5m.”

Investors are not unaware of the potential of indoor farming. AeroFarms, a producer of lettuce and other leafy greens, recently raised $100m, including from Ingka Group, Ikea’s parent company. Bowery Farming raised $95m in a 2018 funding round backed by Google Ventures and Uber boss Dara Khosrowshahi, bringing its total funding to $122.5m.

Bowery Farming has just opened its biggest farm yet in Baltimore. The company uses a custom-built operating system to carefully monitor plants and automatically make changes to improve yield and quality. Cameras track plant growth, and photos are run through algorithms that analyze what’s happening with the crops now and what will likely happen to them in the future.

Bowery’s business plan is partly predicated on the prospect of looming global food shortages. The world’s population is expected to grow by 33% to almost 190 billion by 2050. By that time, farmers will have to produce 70% more food, according to the UN Food and Agriculture Organization. Bowery and its peers see a business opportunity in building massive indoor farms in and on the outskirts of cities, an expensive proposition but one that could reduce on waste and ensure fresher produce.

Indoor farming is not without its detractors. A typical criticism is that it uses a lot of energy for climate control and lighting. For example, lettuces grown in traditional greenhouses in the UK need an estimated 250kWh of energy a year for every square metre of growing area. In comparison, lettuces grown in a purpose-built vertical farm need an estimated 3,500kWh a year for each square metre of growing area.

This is perhaps why the industry has not yet grown as quickly as some predicted. However, the technology is becoming more efficient. In September, Scottish vertical farming tech provider Intelligent Growth Solutions raised £1.6 million in funding, bringing the total to £7 million. According to the company, its tech can reduce energy usage by up to 50% and labour costs by up to 80% compared with other indoor growing environments. It also produces yields of 225% compared to growing under glass. IGS CEO David Farquhar says that the company’s patented tech can be pre-programmed with a ‘weather recipe’ to alter the ‘weather’ conditions automatically using AI.

So while carbon footprint concerns may be valid, indoor farms are set to increasingly draw on renewable energy. The industry is still young and is trying to work out the right business models, but vertical farming could transform global food production forever.

See how Euro Exim Bank can support your growth

For more details www.euroeximbank.com